Welding Nech Radiator Valves DIN 42560 Type A / A OR

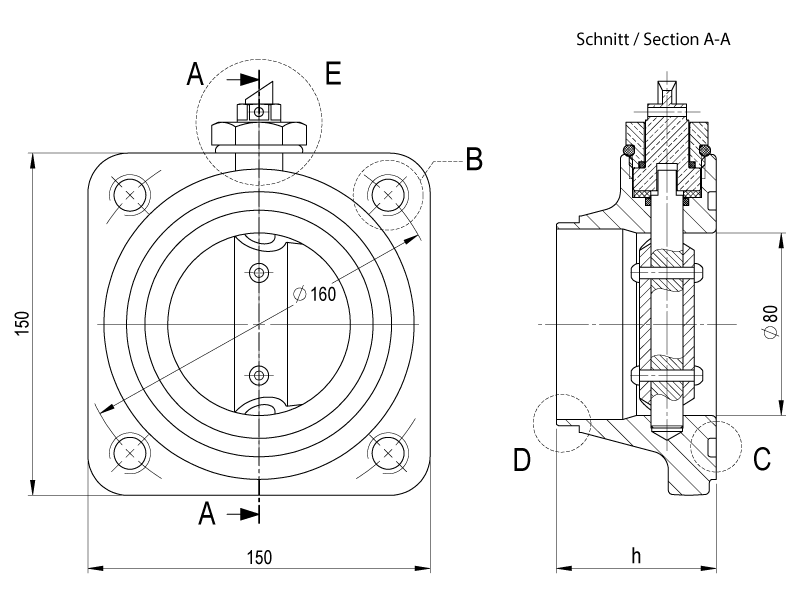

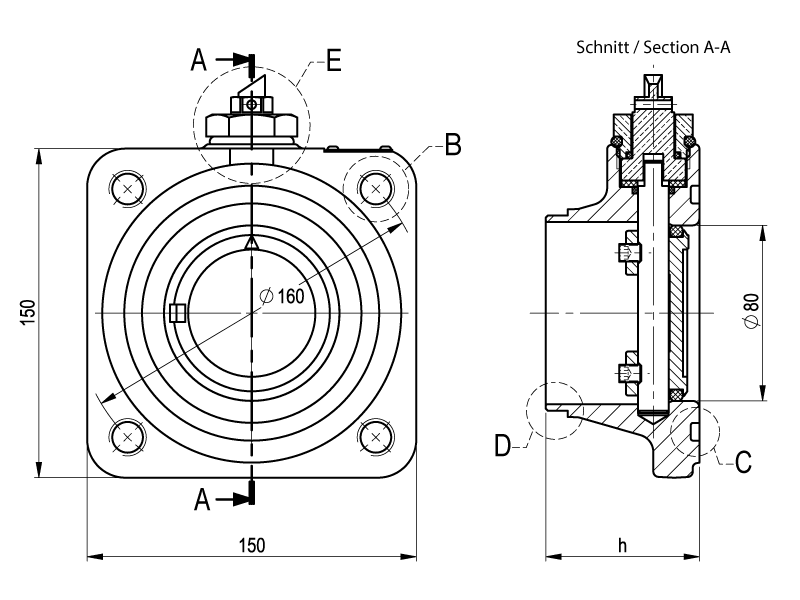

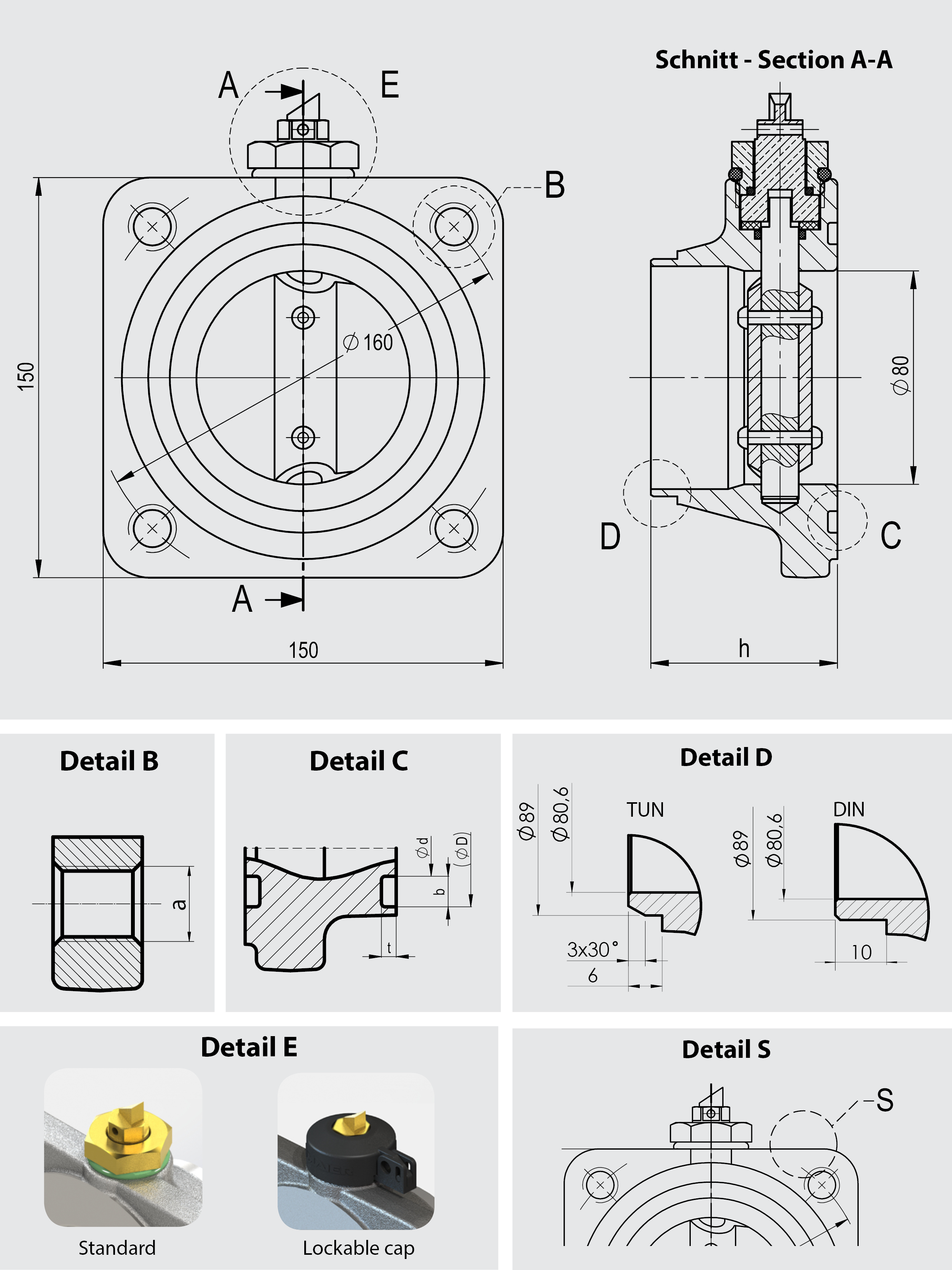

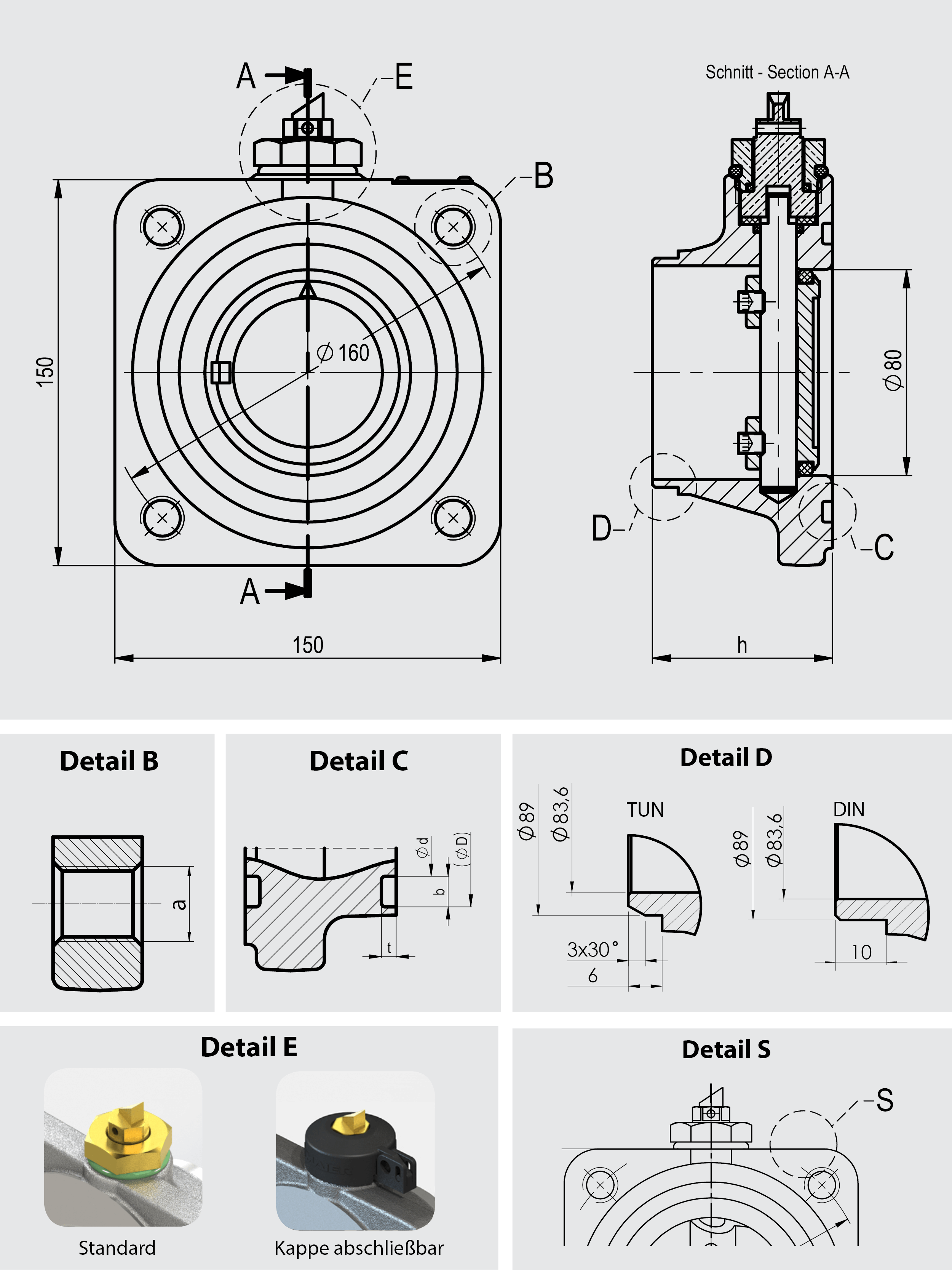

Our transformer radiator valves DIN 42560 type A and A OR are designed to be welded onto the transformer wall or on connection pipes. The radiator will be flanged on the four M16 holes (PCD=160). The housing of the radiator valve is made of forged steel S355J2G3 and thus not subject to any leakage as it may occur with casted housing.

Due to the metal sealed clap a low leakage is permitted while the soft-sealed radiator valve is absolutely oil- and vacuum-tight. Both types are absolutely tight in operation condition to the outside. Our welding neck radiator valves DIN 42560 A NW 80 fulfil the tightness requirements and operating conditions in accordance with DIN 42560 as well as EN 50216-8.

Transformer Radiator Valve Features

- Nominal diameter: 80 mm / square flange

- Type: Welding neck type

- Height h=70 or h=85 mm

- Temperature range: -60 °C up to +125°C

- 4x M16 threads or 18 mm bores

- PCD: 160 mm

- Groove for O-ring-sealing in accordance to customer request

- Valve body (h=70) in stainless steel (AISI 316L)

- Modified welding neck in accordance with customer request

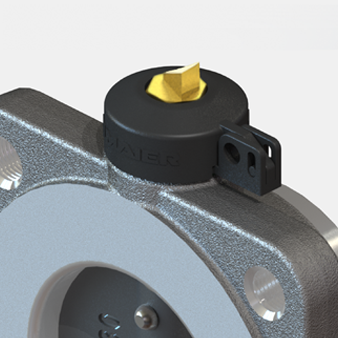

- Setting device in several versions

- Setting device Standard in accordance with DIN 42560 (SW17/SW36)

- Lockable cap

- Lockable handle (only for metal sealed type)

- Handle

Transformer Radiator Valves DIN 42560 Type A and A OR

Metal sealed Soft sealed

Transformer Radiator Valve 42560 type A / A OR for Offshore

Depending on customer requirements, our transformer radiator valves type A and A OR can be equipped for harshest conditions as follows:

- Transformer valve housing material upon request in stainless steel 1.4404 (AISI 316L)

- Setting device standard made of seawater resistant aluminium (EN AW 6082)

- Lockable cap in GRP (glas fibre reinforced plastic)

- Studbolts in stainless steel 1.4404 (AISI 316L) or duplex steel (1.4462)

Ordering options welding neck transformer radiator valves

Request transformer radiator valve / metal sealed

Request transformer radiator valve / soft sealed

Transformer Valve Setting devices

The Setting Device consists basically in all different versions of a thrust member (inner brass part) and a thrust screw (hexagon brass screw). The thrust screw presses the inner thrust member to assure tightness at the area of the spindle. This means that the valve can‘t be operated without loosening the thrust screw.

In case the valve should be welded the device has to be dismounted for welding process to protect sealing materials. The thread has to be protected.

Our transformer radiator valve type A and A OR correspond to type A1 (short and middle) of EN 50216-8.

Our general suggestion is to use our metal-sealed transformer radiator valve for applications where a little leakage could be accepted while assembling/disassembling the transformer radiators due to the maintance-free performance for the transformers lifetime.

Please find below mentioned a comparison of both transformer valve sealing types with advantages and disadvantages as well as the respective ordering options.