Dehydrating Breathers for Transformers

Transformer dehydrating breathers are being used for liquid immersed transformers in order to protect the insulating liquid and prevent the harmful moisture absorption from ambient air, which occurs when the load on the transformer fluctuates.The transformer dehydrating breather removes practically all moisture from the air that flows through it into the conservator when the transformer is cooling down. This largely prevents any reduction of the dielectric strength and the formation of condensation in the expansion tank. Thus, the dehydrating breathers increases the operational safety of transformers.

Our dehydrating breathers are either screwed to the transformer or appropriated by a flange. We offer a variety of different breather types:

- Dehydrating Breather Type L (DIN 42562 / EN 50216-5)

- Dehydrating Breather Type A/B/C (DIN 42567 / EN 50216-5)

- Dehydrating Breather Top mounting 1 ½" and M40 x 1,5

- Dehydrating Breather Without oil stop G 1 ¼"

- Dehydrating Breather 0.150 kg (G 1/2" or G 3/8")

Our transformer dehydrating breathers meet the requirements of EN 50216-5.

By default, our housing parts are made of die casted aluminiumand have a premium class corrosion and UV-resistant C5-M powder coating. Upon request, we offer the housing parts made of EN-GJL-200 gray cast iron (DIN 42562).

Your benefits at a glance

- Best corrosion protection ensures longest operation

- Attachment parts are either in A2 or A4 quality depending on environmental conditions

- Lightweight aluminium design with premium powder coating.

- Quality indicating silica gel made by BASF in favour of long maintenance intervals upon request

The oil container in the lower part of the transformer dehydrating breathers prevents any contact with ambient air as long as the transformer doesn't breathe. In order to ensure this permanently, it is absolutely necessary that the oil container is always filled with oil up to the marked line.

Operating principle transformer dehydrating breathers

-

The transformer is surrounded by moist air. As long as the temperature of the cooling and insulating liquid does not change, no ambient air sucks in or sucks out.

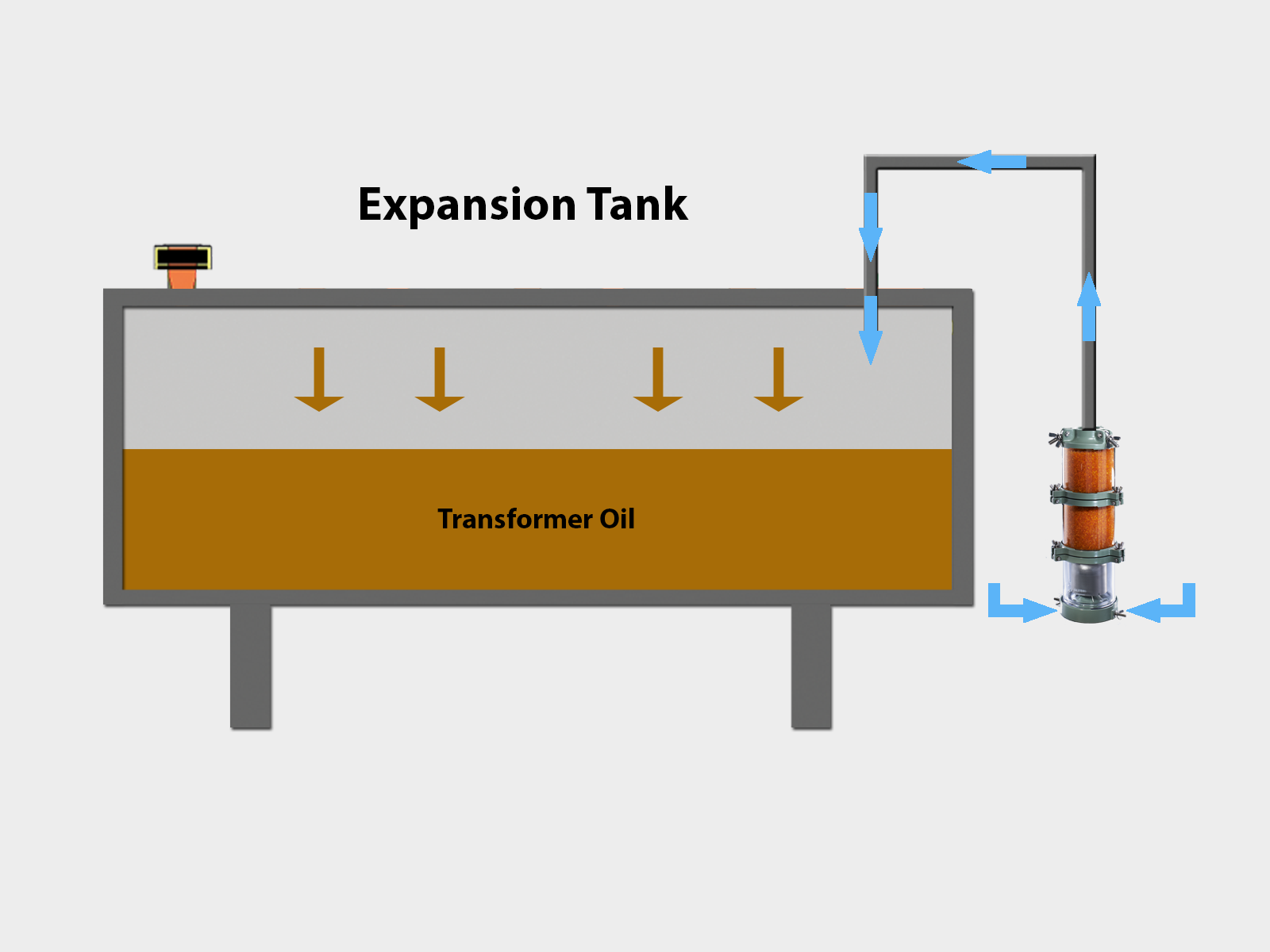

The transformer is surrounded by moist air. As long as the temperature of the cooling and insulating liquid does not change, no ambient air sucks in or sucks out. The cooling and insulating liquid in the transformer cools down, the transformer sucks in humid ambient air through the conservator. The drying agent extracts moisture from the inflowing air and ensures that only the dried air will be aspirated into the transformer.

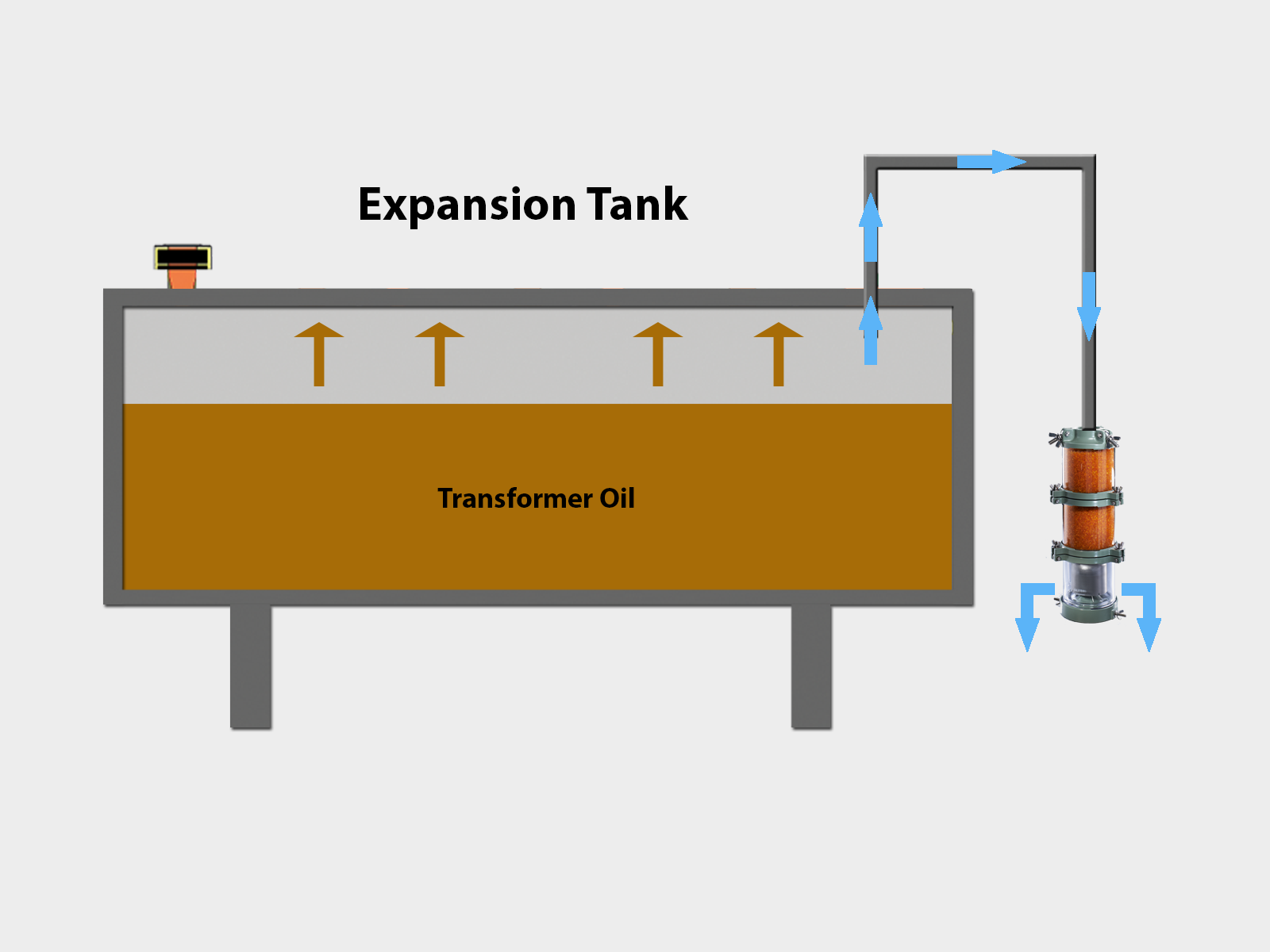

The cooling and insulating liquid in the transformer cools down, the transformer sucks in humid ambient air through the conservator. The drying agent extracts moisture from the inflowing air and ensures that only the dried air will be aspirated into the transformer. The temperature inside the transformer increases. The cooling and insulating liquid expands and displaces the air. The air in the expansion vessel escapes through the conservator and passes the dehydrating breather.

The temperature inside the transformer increases. The cooling and insulating liquid expands and displaces the air. The air in the expansion vessel escapes through the conservator and passes the dehydrating breather. If the dehydrating breather is used properly, no moisture will remain in the transformer, which can lead to condensation any damage.

If the dehydrating breather is used properly, no moisture will remain in the transformer, which can lead to condensation any damage.Transformer dehydrating breather - Silica gel

As a drying agent, we only use silica gel due to the good adsorption properties.The drying crystals are minimum 3mm in size. In activated condition they have a orange crystalline appearance as they absorb moisture the colour changes to colourless, beginning at the bottom and spreading progressively to the top.

Functional check of silica gel

The indications of proper function of the transformer dehydrating breather during changes of temperature are as follows:

- Rising air bubbles in the oil bowl

- Colour of drying crystals changing from orange to colourless beginning at the bottom and spreading slowly upwards

In order to completely exclude any possibility of moisture reaching the conservator, the drying agent should be renewed when there is still a layer of active orange crystals approximately 5 cm thick at the top.

Regenerating the drying crystals

Drying crystals which have absorbed moisture can be regenerated by heating to a temperature of 120-130 °C. A temperature of 140°C should not be exceeded otherwise hydrogen chloride gas will be given off by the colour indicator that could combine with the moisture present to form a dangerous hydrochloric acid.

For more detailed information please find downloads mentioned below.