Buchholz Relay MBP for Transformers

The Buchholz Relay MBP in accordance with EN 50216-2 protects liquid immersed transformers and reactors with conservator.

It will be mounted in the pipeline between transformer and conservator tank.

The Buchholz Relay MBP operates as a protection device that can be provided with either two contacts or four contacts for alarm and tripping. Each Buchholzrelay is individually tested in a test facility for tightness and proper functioning.

Our Buchholz relay MBP is available either in accordance with specifications of the European standard EN 50216-2 or as a special design.

For simplified gas or oil sampling from the ground, you will find our gas sampling device MGSD, which is connected by a copper pipe directly to the Buchholz relay.

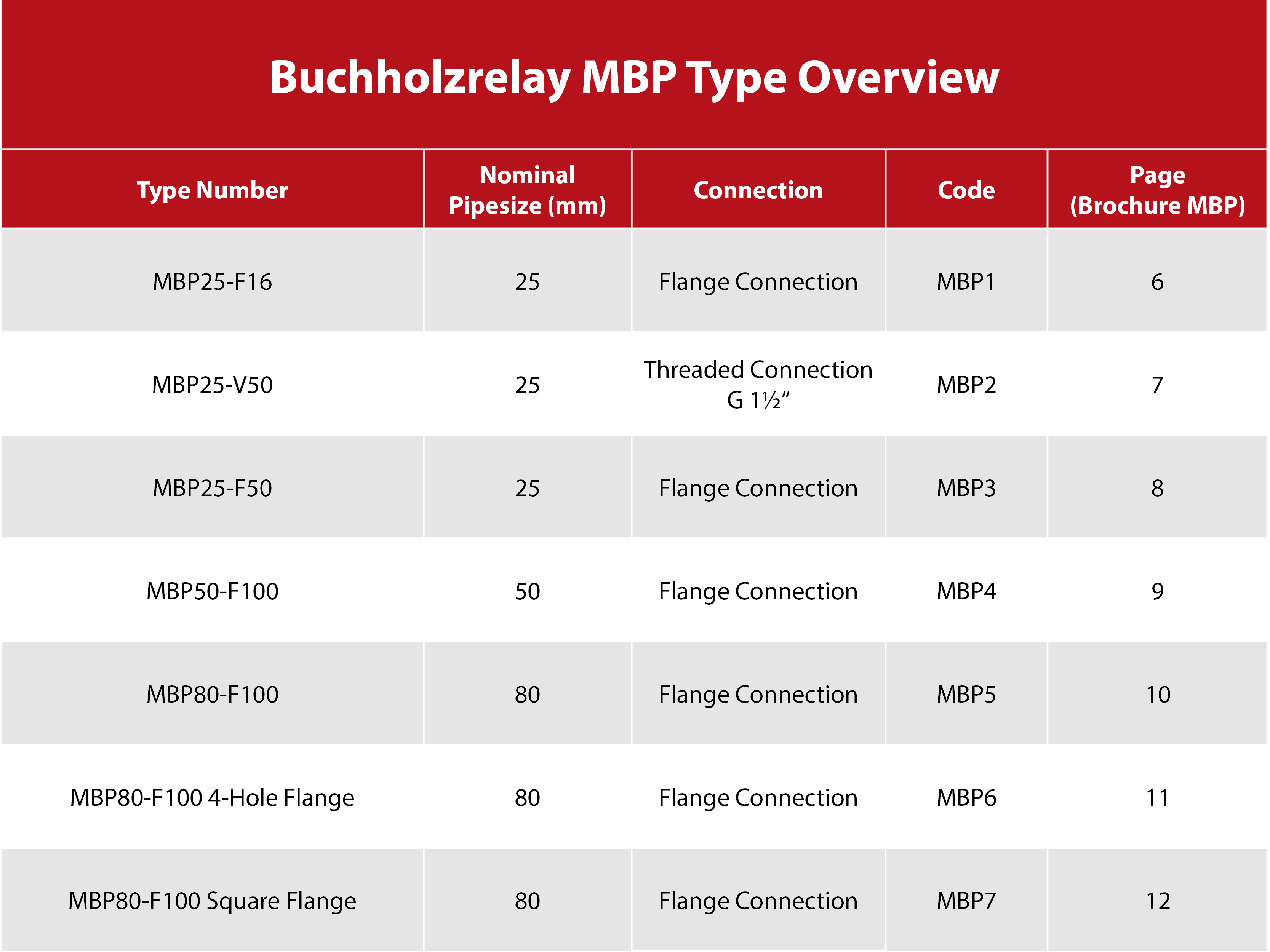

Overview

- Functions in detail

- Your benefits at a glance

- Buchholzrelais MBP in accordance with EN 50216-2

- Buchholzrelais MBP special design

- Gas sampling device MGSD

- Assembling

- Ordering options

- Operating principle

Functions of Buchholzrelay MBP

- Gas accumulation: Gas moves upwards, accumulates in the Buchholz Relay and displaces the insulating liquid. The upper float moves downwards and activates the upper reed switch. The lower float remains unaffected.

- Loss of insulating liquid: If the insulating liquid level drops the upper float moves downwards and switches the upper reed contact. If further insulating liquid level decrease occurs, the pipeline and expansion tank get empty. The lower float moves downwards and actuates the lower reed switch which can be used to deactivate the transformer.

- Increased insulating liquid flow: A sudden pressure wave occurs and moves within insulating liquid. The Flap valve moves in the direction of the pressure wave and actuates the lower reed contact which can deactivate the transformer. After decrease of the pressure wave the flap valve moves back to its origin position.

Your benefits at a glance

- Reed switches for detection of gas formation and dropping oil level

- Flap valve to protect in case of excessive oil flow rate

- Switch elements separated from the oil circuit

- UV-resistant C5-M coating SOLIDLINE

- 1/8“ sampling valve

- Mechanical testing of contact switches (test button)

- Pneumatic simulation (optional)

- High quality materials from a leading manufacturer of Buchholz relay

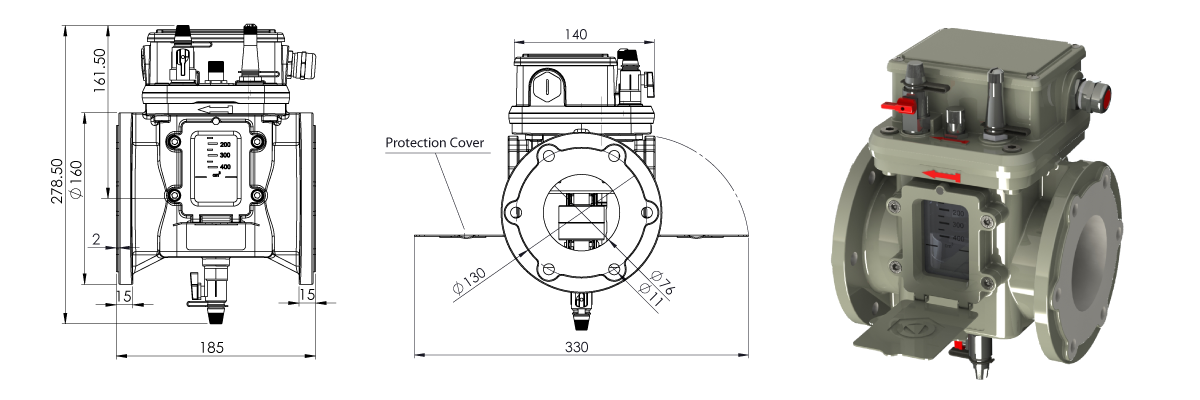

Buchholz Relay MBP in accordance with EN 50216-2

Our Buchholz relay MBP in accordance with EN 50216-2 complies with the requirements of European standard EN 50216-2. The standard specifies among others operating limits, dimensions, performance and electrical characteristics. The die-cast aluminum housing in combination with the C5-M powder coating offers the highest level of UV and corrosion resistance. Properties of our Buchholz relay MBP are:

- Nominal pipe diameter: DN 25 (1"); DN 50 (2"); DN 80 (3")

- Connection: Flange connection (DN 25 also with thread connection G 1 1/2")

- Switching element: Reed switches

- Number of switching contacts:up to 2 NO or 2 CO (SPDT) contacts per function

- Ambient temperature: -30 °C bis 55 °C

- Degree of protection: IP65 (optional IP68)

- Insulating liquid flow speed: 0,65 m/s; 1,00 m/s; 1,50 m/s; 2,00 m/s

- Flap valve: Magnetically held

- Gas volume for response: 200 cm³ - 300 cm³

- All commonly used RAL colors for transformers

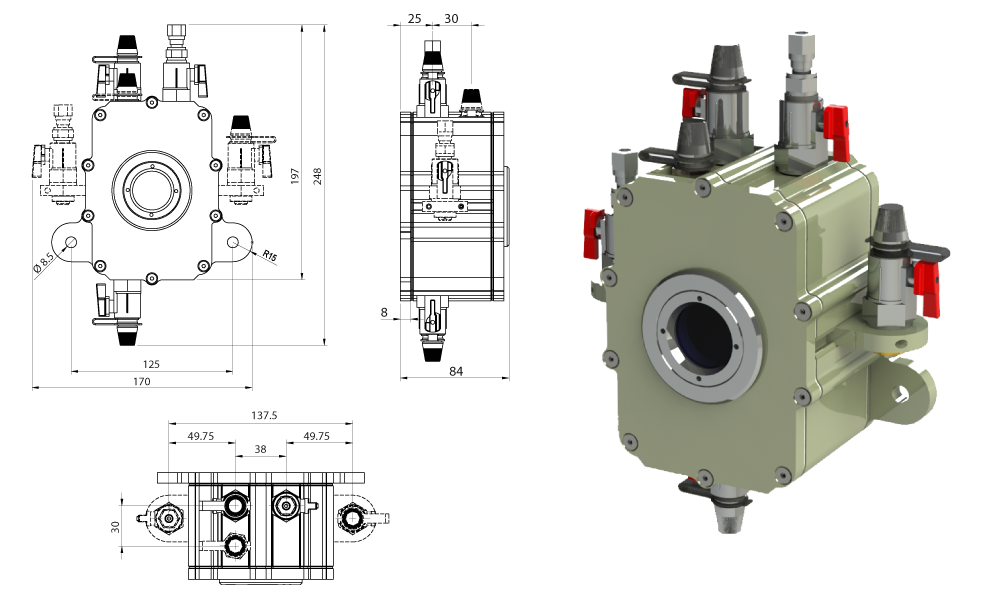

Buchholz Relay MBP Special Design

The special design was developed according to customer requirements. While the functions are the same, the most significant differences are flange dimension, bolt circle, nominal diameter DN76 and housing width.

Gas Sampling Device MGSD

For large power transformers, the Buchholz relay is assembled at a height that is difficult to access (between tank and the expansion tank).

The gas sampling device MGSD is connected to the Buchholz relay by a copper tube and can be mounted anywhere on the transformer.

It is used for simplified gas or oil sampling from the ground. Optionally available is an additional oil sampling valve and a valve for pneumatic functional testing of the switches.

Assembly of Buchholz Relay MBP

The Buchholz Relay will be installed between transformer and expansion tank. For properly assembly of Buchholz Relay MBP the following aspects must be considered.

- The red arrow points towards the expansion tank (arrow shows flow direction).

- The angle of the pipeline towards the expansion tank must not be less than 0° and not exceed a max. of 5°.

- Arising gases must be able to reach the Buchholz Relay without hindrance.

We are a leading manufacturer of Buchholz relay for transformers and put a lot of efforts in continuously developing special designs matched with customers requirements. For further detailed information regarding the various Buchholz Relay MBP types as well as possible ordering options (brochure page 13), please refer to our brochure below.

Request Buchholzrelay MBP

Buchholz relay - operating principle